Our motto: “Everyone may optimize a product design, the true challenge is doing so safely, at a high quality and economically fast enough so that it sustainability scales with profitability.”

Our mission? To build a place where everyone can leverage the world’s best-in-class computational and mathematical innovations to create novel, valuable and sustainable products.

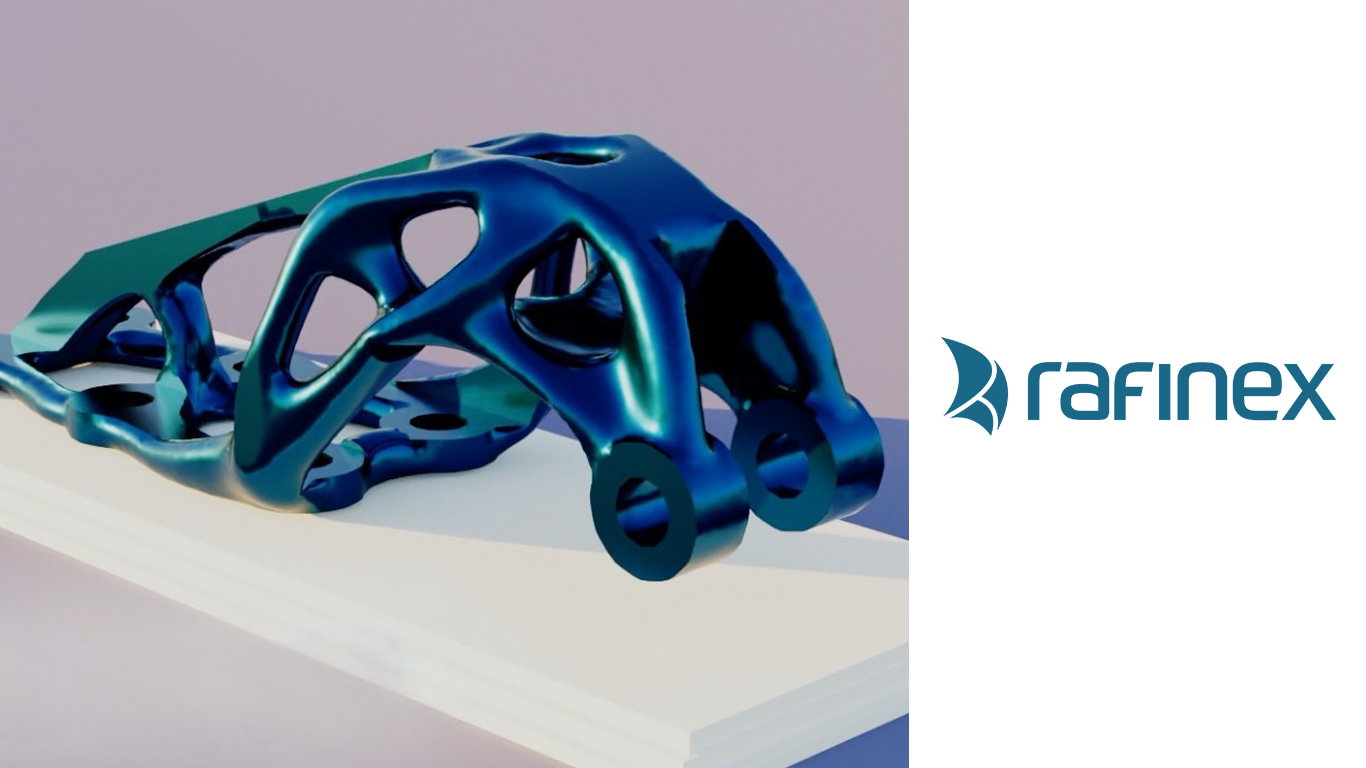

Who are we? The biggest problem in advancing design engineering is estimating and managing risk. Bad designs are costly, driving 80% of a product’s lifecycle costs & 70% of its environmental impact, while the risk of failure is ever present for products that face billions of unknown factors and conditions when they are used in real-life scenarios. By developing next-gen optimization algorithms for engineering design, Rafinex provides engineers with realistic digital tools to help manage risk, tackle the cost of ‘bad’ or unoptimised designs, and generate optimal designs they can trust in real-life operations within minutes to hours.

Rafinex’s technology…

- Is built into a SaaS software product called “Möbius”

- Is used by OEMs in the automotive, tooling, aerospace, defence and white goods industries

- Allows engineers to go from a coarse idea to a fully validated design rapidly

- Manages and quantifies costly risk factors

- Enables engineers to optimize with confidence, making fast and informed decisions

- Helps design high-quality, better-performing, trustworthy, robust, efficient, and resilient products

- Helps reduce waste of materials, energy consumption, and production resources

- Enables sustainability to become profitable at scale

- Helps capture increased value along the product lifecycle

The lightbulb moment? Rafinex emerged from a drive for excellence in digital engineering. The founders all have deep backgrounds in advanced numerical methods of academic research. However, when transitioning to industry, we were met by capability limitations which we knew had already been solved at world-leading academic institutions. This led to us creating Rafinex as a spin-out from the WIAS institute in Berlin, quickly gaining automotive OEM customers and maturing cutting-edge optimization algorithms in an industrial setting.

Why did we apply for Sixth Sense? Rafinex cannot thrive in isolation. Our solution specifically addresses the inclusion of real-life variability and input data from other digital engineering software solutions. Hence, there are synergies to closely integrate into the digital software toolchain of the ecosystem to provide better and more value to every stakeholder. Sixth Sense is an excellent platform to demonstrate what joint integration can achieve by showcasing a real-application demonstrator design, as well as how the digital tools and IoT sensors from Hexagon can be interconnected with Rafinex.

Where do we hope to be in five years’ time? We are in the process of transitioning from a startup to a scaleup following the successful maturing of our core technology components. In five years’ time, we aim to expand our customer base worldwide in both our current active sectors as well as new industrial sector applications. We strive to be known for design optimization excellence.

Which emerging technologies excite us? The advent of mixed-manufacturing methods is very exciting as it opens the doors to new design freedoms that have commercially acceptable unit costs in mass production. In particular, we are interested in crossovers between classical manufacturing methods, such as casting and newer methods, such as additive manufacturing, particularly wire-arc additive manufacturing. The ability to add up features using additive manufacturing onto a raw baseline plate or stock item is very interesting for customizing the weight of product variants.