The mission

“Rethink industrial 3D”

Threedy’s goal is to simplify the availability of industrial 3D data to leverage its true value.

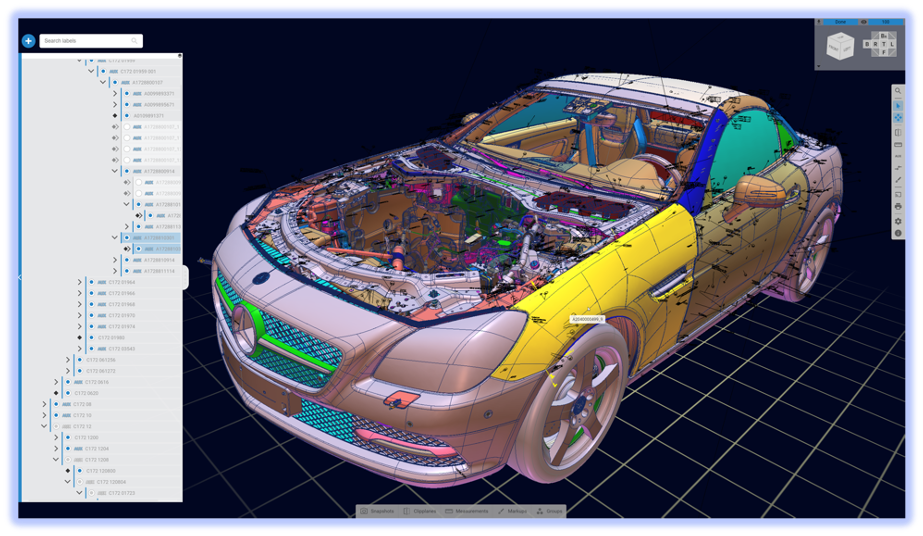

By abstracting the complexity of the 3D/XR domain, Threedy’s technology enables customers to build even the most complex industrial applications – directly leveraging full quality CAD or construction data.

This creates totally new possibilities to exploit the real value of 3D data throughout the entire value chain, in a new way, making it accessible to everyone and anywhere.

Threedy’s data-driven, end-to-end solution for scalable visual computing enables the hyperconnectivity required in the industrial space for a wide range of application scenarios, platforms, and devices to enable Digital Twins or Industrial Metaverse implementations.

The problem

Complex 3D data is the foundation of successful engineering in the industry. But the data is not easily available – sharing ideas with colleagues and clients, bringing most complex data to the shopfloor or utilising it for remote maintenance scenarios – has always been cumbersome.

“Companies working with complex 3D data are always faced with decisions like size or type of data, compute distribution or data conversion pipelines to finally use 2D pixel streams or flat pictures to clients’ devices like smartphones, so they’re moving data from A to B,” says Stefan Domdey, Threedy. “We virtualise the data and compute, therefore enabling output-sensitive solutions.”

What we do

Threedy offers visual computing technology as an infrastructure component to enable large scale and complex 3D data.

“We enable really complex data anywhere,” says Domdey. “So that our clients can build their own custom 3D apps while respecting the single-source-of-truth of their data. Data virtualisation and the computing of that data with uploads to the cloud or other platforms are not necessary anymore!”

In modern IT and software landscapes, industrial 3D data and applications are often considered foreign bodies requiring special treatment as a result of the enormous interdependency and complexity of data size, algorithms, and device capabilities.

“For manufacturing, 3D data is currently stuck in the engineering process,” he says. “With our infrastructure component, we give companies the chance to harness 3D data’s true value – leveraging complex datasets throughout the entire value chain – which increases productivity and introduces cost savings on a number of fronts.”

Our history

Threedy was spun-off from a German research institute, Fraunhofer IGD, where the team was built over the course of almost ten years.

“The technology was part of several projects with various industrial customers,” explains Domday. “When BMW issued a tender asking for a technology to enable complex 3D in a browser. The team from Fraunhofer IGD used previous software generations of today’s instant3Dhub to win this tender to set the foundation of today’s technology and company.

“So, BMW was the very, very first customer and of course the automotive industry is pretty small, people started talking about us and saw that there was value in the technology and a uniqueness to the approach.”

While it grew out of automotive, Threedy also works with the process industry and with specialist machinery builders. Any industry that deals with complex data can be a target.

Interesting fact about Threedy

Threedy has recently joined the Metaverse Standards Forum as well as German initiatives IDTA and Catena-X – spaces where companies and organisations explore interoperability. “For us, it’s part of our DNA,” says Domdey. “To bring this kind of experience and hyperconnectivity to everyone in an organisation. The topics being discussed are things we’ve been talking about for decades.”

What we hope from Sixth Sense

“We applied for Sixth Sense because it gives us a great chance to explore and utilise synergies with Hexagon’s ecosystem, and we saw opportunities for our two companies to elevate each other’s innovation,” says Domdey.

“In terms of output, we are looking at the possibilities of partnerships that will extend the usage of industrial 3D within the Hexagon ecosystem. We want to enable the manufacturing industry to build the 3D applications they require to constantly improve their business throughout the entire value-chain.”