Our mission? To empower industrial worker productivity in an age of automation and digitisation

How? By connecting workers with real-time insight and context-specific instruction – guiding them on what to do, when to do it and how to do it. A big part of this involves capturing the “know-how” of experienced workers and making it available to new workers, as well as using data to direct work and using AI to deliver contextually relevant guidance. We offer an easy-to-use, fast-to-adapt no code platform for digitising daily operational workflows and capturing operational knowledge.

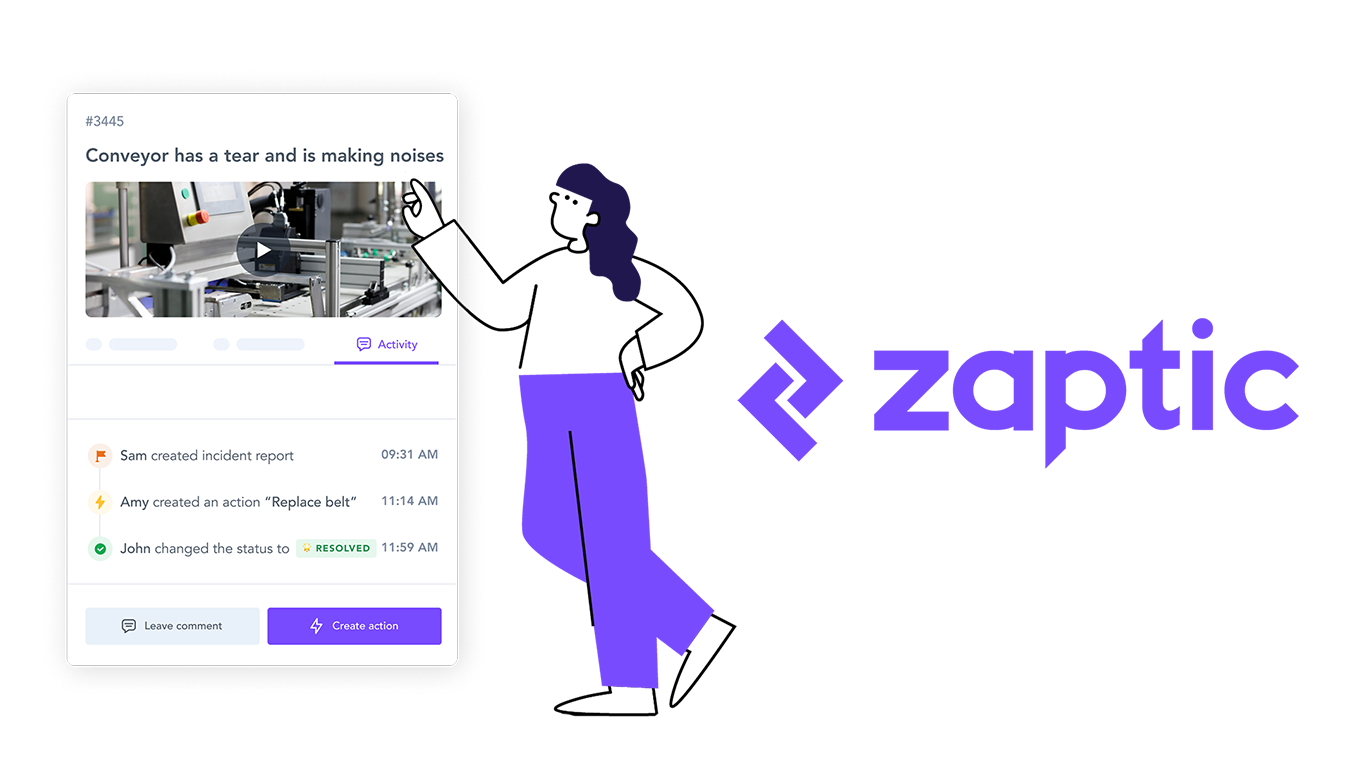

Zaptic’s technology…

- Digitally transforms frontline operations – often reliant on paper, whiteboards and siloed knowledge

- Provides a digital knowledge base – key to solving the workforce onboarding challenge

- Surfaces context-specific knowledge using AI – guiding and augmenting workers on the job

- Bridges skills gaps and overcomes workforce variability – helping to avoid losses

- Brings factory workers online – critical for modern collaboration and building a true digital reality

- Boosts productivity and agility – removing capacity constraints by bridging knowledge gaps

- Futureproofs the workforce – helping to attract, train and retain frontline workers

- Can be used for autonomous maintenance, quality checks, safety observations, checklists, audits and more

The lightbulb moment? It all started when Richard, our CEO, was working on a custom app build for Unilever out of his university digs. They wanted an app to help guide field reps in identifying why products went out of stock in retail stores, as well as how to fix this. It soon became apparent that there was an even greater need for the same type of solution to guide and capture daily execution and problem-solving in manufacturing operations, with the opportunity to build a shared knowledge base with the potential to transform workforce development to help overcome a global skills shortage. And so Zaptic was born. We hired manufacturing experts, collaborated closely with our first customers, and have been working very hard ever since!

Why did we apply for Sixth Sense? We were interested in the possibility of accelerating areas of new product development and receiving highly relevant feedback from the Hexagon ecosystem, as well as exploring partnership opportunities.

Where do we hope to be in five years’ time? We have already managed to secure six of the world’s largest alcoholic beverage producers as customers. In five years, we want to be successfully easing the transition to a new generation of manufacturing workers, with tens (perhaps hundreds) of millions of users relying on Zaptic to work safely, efficiently and effectively every day.

Which emerging technologies excite us? We are super excited about the potential for generative AI to help us guide workers in a highly customised, personalised and interactive way, including the use of work instruction generated automatically with AI. Augmented reality is also very exciting in this context.