The inspiration from everyday life

When MIT professor and neuroscientist Ted Adelson had his daughter, it changed his life far beyond the usual sleep deprivation. Professor Adelson, one of the world’s experts in human and machine vision, became obsessed with touch.

“His whole career was about how human vision works and how you can tie that to computer vision,” explains GelSight CEO Youssef Benmokhtar. “But when his daughter was born he was actually fascinated by the fact that an infant relies on touch more than vision to explore the world in its first few weeks. It was an Isaac Newton moment. He decided to switch fields.”

Adelson posed the question – is there way to build a sensor that is soft like a human finger and can capture touch signals with high sensitivity? “Now MIT is a place where things happen,” says Youssef. “Everyone said no, nothing like that exists today. So, he got to work in his garage and came up with the gel material that we use in our sensors.”

With the skin-like sensitive gel created, Professor Adelson needed to transfer the data from the sensor. Given his history as an expert in vision, he decided to put a camera behind the gel, so the camera could see what the gel feels. “That’s how simple it is,” says Youssef, “It’s like having a camera inside your finger. That’s the genesis of the company.”

Developing a product

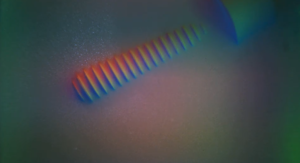

Spun out of MIT, GelSight’s tactile intelligence technology now digitises touch with human-like sensitivity. Most commonly used as a handheld device (but can also be mounted onto robotic arms), GelSight’s products have a soft, high-resolution, tactile sensor that conforms like human skin to the shape of an object on contact, precisely capturing the topography of the surface.

“Wherever vision struggles or is not capable of giving you the understanding of the physical world, such as on a transparent surface or in bright or low light, GelSight provides you that understanding through touch,” says Youssef.

Co-founder Kimo Johnson, who we also worked closely with during the Sixth Sense programme, took Professor Adelson’s sensor and created the algorithms behind it. “These allow you to create a 3D map of anything the sensor touches,” explains Youssef.

When the innovative system was first invented, Professor Adelson was working on understanding how it could give robots the same sense of touch as humans. Would this enable them to start doing complex object manipulations? As the product progressed, it became clear that one of the best use cases for the invention was in surface inspection.

Finding a real-world application

“The fact that our device works in any environment, makes it a really good metrology device,” explains Youssef. “It’s accurate to the micron level – beyond millimetres and not quite nanometers.”

This minute accuracy has meant that GelSight’s biggest customer base to date has been in the aerospace industry – searching for scratches and dents in the fuselage, wings, and airframes of aircraft. “Aerospace is a high precision industry,” says Youssef. “They really care about the microns because when an aircraft flies, there is so much force applied to every part of the plane that a tint crack could mean potential engine failure or an airframe breaking.”

With customers such as Rolls Royce (aerospace), French aircraft maker Safran and cargo company Kalitta Air – about half of GelSight’s revenue comes from aerospace. GelSight is enabling a traditional industry to digitise a historically analogue, manual action.

“A lot of these factories have been using what they call the ‘fingernail test,’” says Youssef. “They have just been scratching the surfaces with their nails and saying whether something feels out of spec or not. We replace that method so that it is no longer subjective.”

This is an extract from a longer profile on GelSight which will be published in Hexagon’s magazine this summer.