Insights

Sixth Sense Summit 2024 in London: what to expect

The culmination of the Third Challenge – the Sixth Sense Summit in London – is coming up in just one week! Date: Wednesday 7th February 2024 Registration: 2.30 pm, where you’ll have a chance to explore the exhibition Panel discussions and pitching competition: 3.45 pm-5.30 pm Winner revealed: 6.00 pm Networking reception: 6.00 pm-7.00 pm Location: CodeNode, 10 South Pl, London EC2M 7EB The event will host 150 industry leaders from across manufacturing, technology, engineering and more, bringing founders and funders together to connect for an afternoon of exhibitions, roundtable discussions, on-stage content and networking. The culmination of the event will happen in the evening, with Sixth Sense’s third cohort of start-ups pitching their groundbreaking solutions and competing for the chance to build a long-lasting partnership with Hexagon. Register to attend the event here if you haven’t already to secure your spot as the Sixth Sense Summit countdown continues! Sixth Sense Summit Program Highlights 14:00 – Roundtable Discussions Please note that you can join the roundtables by invitation only. Please email us at HexagonSixthSense@wearesevenhills.com if you want to express an interest in participating. Roundtable 1: Improving Female Representation in Manufacturing Host: Russ Shaw CBE, Founder of Tech London Advocates and Global Tech Advocates Guests: Senior representatives of Hexagon, Lloyds Banking Group, EngineeringUK, University of Cambridge, Women's Engineering Society, TLA Women in Tech and more. Discussion: Women account for 26% of workers in UK manufacturing, earning on average 17% less than their male peers. And the picture is no better abroad. At a time when investment in the sector is falling, and many traditional manufacturing processes are being superseded by technology – another male-dominated sector – this roundtable explores the steps required to increase female representation in the industry. Roundtable 2: Fundraising in a Challenging Climate Host: Elaine Warburton OBE, Founder & NED ReadyGo Diagnostics Guests: Senior representatives of Industrial Innovation Venture Fund, UK Business Angels Association, Dawn Capital, Hoxton Ventures, EIT Digital and more. Discussion: A sharp fall in fundraising activity in 2023 highlights the challenging environment facing early-stage companies today. This roundtable will bring together both funders and founders to discuss how we address and overcome the barriers to secure investment and how startups themselves can ensure that they stand out from the crowd when funding is hard to come by. Roundtable 3: Spotlight on Spin Outs Host: Ana Avaliani, Director of Enterprise and Sustainable Development at the Royal Academy of Engineering Guests: Senior representatives of AMRC, London Space Innovation Centre, Scaleup Institute, City, University of London and more. Discussion: Spin outs play a crucial role in the UK's ambition to become a 'science and technology superpower.' With the investment of £5.3bn in 2021, the UK stands as the second-largest hub for spin out investment globally, behind the US. Despite this success, challenges persist in optimising the entrepreneurial potential of the UK's top-tier universities. This roundtable will look at solutions to those challenges, including intellectual property management, securing funding for proof-of-concept and fostering entrepreneurial learning. 14:30 – Registration,

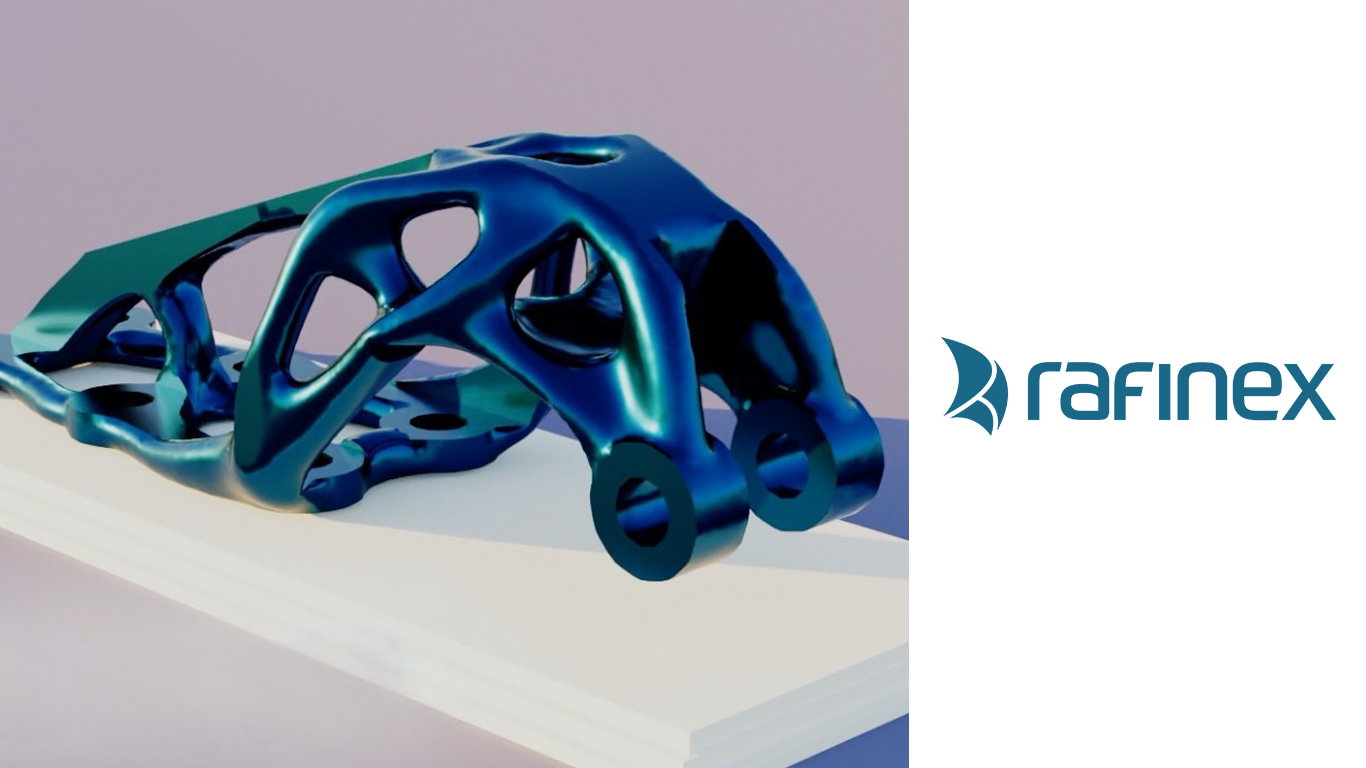

Cohort Three Spotlight: Rafinex

Our motto: “Everyone may optimize a product design, the true challenge is doing so safely, at a high quality and economically fast enough so that it sustainability scales with profitability.” Our mission? To build a place where everyone can leverage the world’s best-in-class computational and mathematical innovations to create novel, valuable and sustainable products. Who are we? The biggest problem in advancing design engineering is estimating and managing risk. Bad designs are costly, driving 80% of a product’s lifecycle costs & 70% of its environmental impact, while the risk of failure is ever present for products that face billions of unknown factors and conditions when they are used in real-life scenarios. By developing next-gen optimization algorithms for engineering design, Rafinex provides engineers with realistic digital tools to help manage risk, tackle the cost of ‘bad’ or unoptimised designs, and generate optimal designs they can trust in real-life operations within minutes to hours. Rafinex’s technology… Is built into a SaaS software product called “Möbius” Is used by OEMs in the automotive, tooling, aerospace, defence and white goods industries Allows engineers to go from a coarse idea to a fully validated design rapidly Manages and quantifies costly risk factors Enables engineers to optimize with confidence, making fast and informed decisions Helps design high-quality, better-performing, trustworthy, robust, efficient, and resilient products Helps reduce waste of materials, energy consumption, and production resources Enables sustainability to become profitable at scale Helps capture increased value along the product lifecycle The lightbulb moment? Rafinex emerged from a drive for excellence in digital engineering. The founders all have deep backgrounds in advanced numerical methods of academic research. However, when transitioning to industry, we were met by capability limitations which we knew had already been solved at world-leading academic institutions. This led to us creating Rafinex as a spin-out from the WIAS institute in Berlin, quickly gaining automotive OEM customers and maturing cutting-edge optimization algorithms in an industrial setting. Why did we apply for Sixth Sense? Rafinex cannot thrive in isolation. Our solution specifically addresses the inclusion of real-life variability and input data from other digital engineering software solutions. Hence, there are synergies to closely integrate into the digital software toolchain of the ecosystem to provide better and more value to every stakeholder. Sixth Sense is an excellent platform to demonstrate what joint integration can achieve by showcasing a real-application demonstrator design, as well as how the digital tools and IoT sensors from Hexagon can be interconnected with Rafinex. Where do we hope to be in five years’ time? We are in the process of transitioning from a startup to a scaleup following the successful maturing of our core technology components. In five years' time, we aim to expand our customer base worldwide in both our current active sectors as well as new industrial sector applications. We strive to be known for design optimization excellence. Which emerging technologies excite us? The advent of mixed-manufacturing methods is very exciting as it opens the doors to new design freedoms that have

Cohort Three Spotlight: Zaptic

Our mission? To empower industrial worker productivity in an age of automation and digitisation How? By connecting workers with real-time insight and context-specific instruction – guiding them on what to do, when to do it and how to do it. A big part of this involves capturing the “know-how” of experienced workers and making it available to new workers, as well as using data to direct work and using AI to deliver contextually relevant guidance. We offer an easy-to-use, fast-to-adapt no code platform for digitising daily operational workflows and capturing operational knowledge. Zaptic’s technology… Digitally transforms frontline operations – often reliant on paper, whiteboards and siloed knowledge Provides a digital knowledge base – key to solving the workforce onboarding challenge Surfaces context-specific knowledge using AI – guiding and augmenting workers on the job Bridges skills gaps and overcomes workforce variability – helping to avoid losses Brings factory workers online – critical for modern collaboration and building a true digital reality Boosts productivity and agility – removing capacity constraints by bridging knowledge gaps Futureproofs the workforce – helping to attract, train and retain frontline workers Can be used for autonomous maintenance, quality checks, safety observations, checklists, audits and more The lightbulb moment? It all started when Richard, our CEO, was working on a custom app build for Unilever out of his university digs. They wanted an app to help guide field reps in identifying why products went out of stock in retail stores, as well as how to fix this. It soon became apparent that there was an even greater need for the same type of solution to guide and capture daily execution and problem-solving in manufacturing operations, with the opportunity to build a shared knowledge base with the potential to transform workforce development to help overcome a global skills shortage. And so Zaptic was born. We hired manufacturing experts, collaborated closely with our first customers, and have been working very hard ever since! Why did we apply for Sixth Sense? We were interested in the possibility of accelerating areas of new product development and receiving highly relevant feedback from the Hexagon ecosystem, as well as exploring partnership opportunities. Where do we hope to be in five years’ time? We have already managed to secure six of the world’s largest alcoholic beverage producers as customers. In five years, we want to be successfully easing the transition to a new generation of manufacturing workers, with tens (perhaps hundreds) of millions of users relying on Zaptic to work safely, efficiently and effectively every day. Which emerging technologies excite us? We are super excited about the potential for generative AI to help us guide workers in a highly customised, personalised and interactive way, including the use of work instruction generated automatically with AI. Augmented reality is also very exciting in this context.

Cohort Three Spotlight: Acerta

Our mission? Enabling the understanding of the digital thread for every vehicle. We help manufacturers understand complex production data better, predict quality issues, and accelerate root cause analysis. Who are we? With manufacturing operations becoming increasingly digitised, there is a growing treasure trove of data being generated that is becoming impossible to analyse manually. To help manufacturers get value out of the data they are already producing, we created a predictive quality platform called LinePulse that uses it to improve quality, automate root cause analysis, and get an early indication of any issues that may impact production. By operationalising machine learning, LinePulse provides information and advanced analysis in real-time to line engineers and quality teams. LinePulse sends alerts before problems arise, identifies where process improvements should be implemented, and equips them with insights to understand complex processes and make better day-to-day decisions. Acerta’s technology helps manufacturers and line engineers to… Predict quality issues to avoid problems downstream Reduce recall, retest, rework, and scrap rates Automate root cause analysis Avoid quality spills which could lead to costly warranty failures Make better, faster, and data-driven decisions Bring new products to market faster Reduce waste in factories and in the field Streamline and optimise electrical vehicle production The lightbulb moment? During our time at the University of Waterloo, researching the applications of machine learning and AI for the large amounts of data being generated from industrial machinery (e.g., drones, cars, and planes), our observations sparked an idea. We noticed that whilst a lot of automation and complex systems were being built into vehicles, the process of demonstrating they work as expected was still very manual. We also noticed that a large amount of information was becoming available from these products and manufacturing processes. We aimed to combine the two, bringing that into the automotive lifecycle. Why did we apply for Sixth Sense? Hexagon has a huge presence in manufacturing, including more traditional solutions around quality control and quality management, and Acerta brings machine-learning data techniques and cloud software to the factory. Our hope is that, in partnership together, we can create a more holistic, data-driven, and modern end-to-end quality solution for manufacturers – combining the strengths of both companies. It's a partnership that can really create a lot more value for manufacturers. Where do we hope to be in five years’ time? Right now, we're focused on bringing our technology to the automotive and off-highway industries. However, our solutions are also broadly applicable to other manufacturing sectors, whether it be medical devices, electronics or other solutions. In the next three to five years, our goal is to broaden the reach and applicability of our platform to other industries in the broader discrete manufacturing space – especially with companies like Hexagon. Which emerging technologies excite us? The most exciting for us is generative AI because these large language models open up opportunities to improve the way line engineers interact with human-machine interfaces. Instead of spending time clicking around and figuring out how to query

Cohort Three Spotlight: Dessia

Our mission? Empowering tomorrow's engineers with AI. Who are we? We believe that automation is the main challenge in engineering, so we’re developing an AI-based platform that allows engineers to structure and leverage their knowledge – assisting them in everyday tasks and allowing them to make faster, better design decisions. How does it work? Our platform is non-specific – for example, we provide automation for electrical wiring as well as cooling architectures for electric vehicles – and we offer it to major players in the automotive, aerospace, space, and defence industries, helping them improve their productivity by automating their design processes. Dessia’s platform… Structures technical engineering knowledge into intelligent design workflows. Helps engineers and architects make better design decisions. Assists industrial companies in digitising their engineering processes. Provides engineers with virtual design companions called ‘engineering bots’. Uses ‘explainable AI’, helping users better understand algorithms and their outputs. Generates thousands of design options early in the product development cycle – in just a few hours. Aims to help engineers design products with lower carbon impact. Is versatile, able to be specifically tailored for different industries. The lightbulb moment? During his ten years at PSA, our CEO and founder, Pierre-Emmanuel, consistently encountered a major challenge: being unable to successfully automate design tasks to identify the optimal solution. These initial experiences were the catalyst for founding Dessia six years ago. Our goal was to democratise these innovative methodologies and make them accessible to the entire engineering sector through a universal framework. Why did we apply for Sixth Sense? We aim to bring more value to our clients by offering them more accurate simulations – enabling them to make more informed architectural choices. Therefore, we wish to explore the possibility of connecting our platform to Hexagon's numerous simulation software solutions. Where do we hope to be in five years’ time? We are currently in the process of fundraising to scale up at the European level, and we aspire to become the leader in Europe in digitising engineering processes. Which emerging technologies excite us? Automation through AI is exciting and offers numerous prospects for engineering, such as aiding the automotive and aerospace industries in reducing their development time.

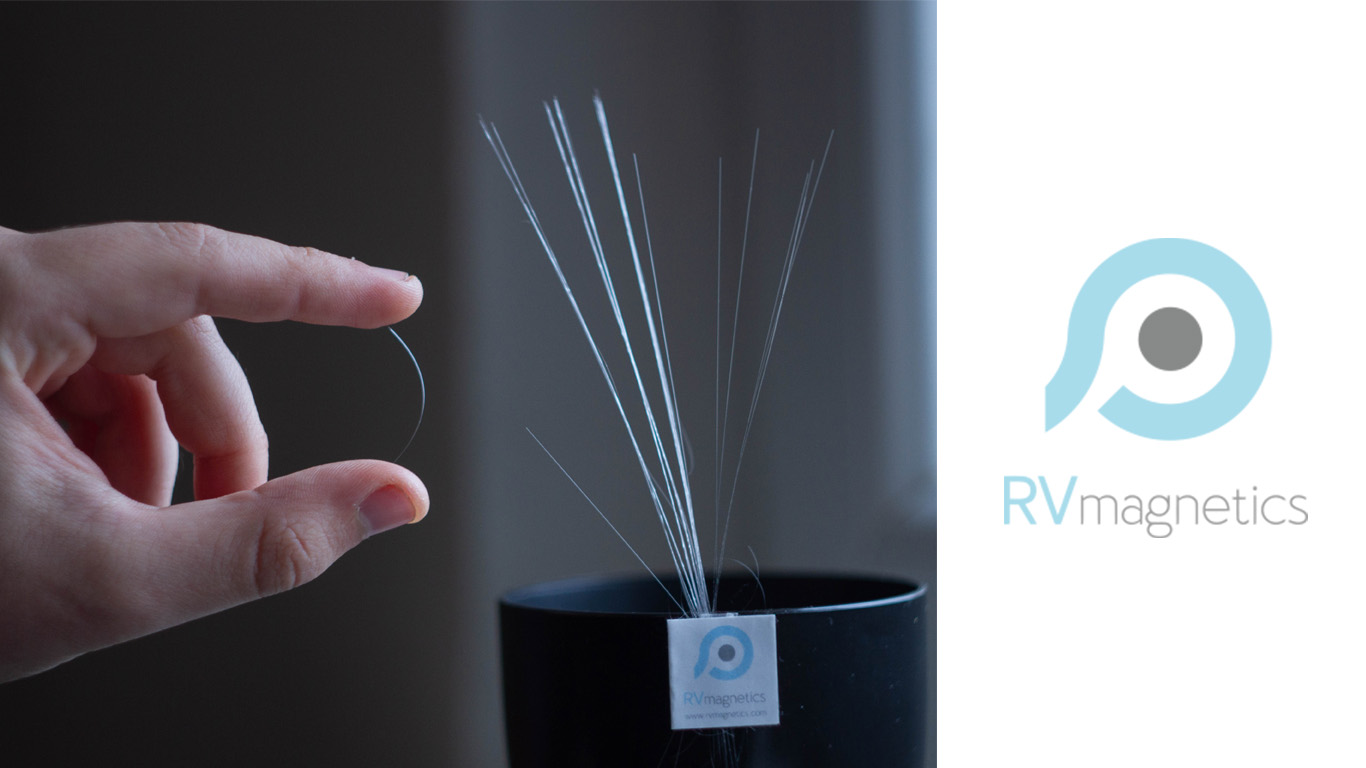

Cohort Three Spotlight: RVmagnetics

Our mission? To help manufacturing clients measure data in challenging environments using the world’s smallest passive sensors, known as MicroWires. Who are we? An R&D-driven company with proprietary sensing technology that is able to “mine” data in conditions that have limited or no other measurement solutions thus far. Our tiny MicroWire sensors are compact, robust and contactless devices that are able to detect a wide range of otherwise undetectable physical data – from inaccessible spaces, with accuracies, and within timescales not otherwise possible. With this technology, we aim to provide niche and unique measurement solutions to industries including automotive, medical technology, aviation and consumer goods. This could be anything from environmental monitoring – measuring temperature, humidity, pressure, or air quality in different environments; to industrial processes – including pH sensing, temperature sensing, and pressure sensing for process control and monitoring. RVmagnetics’ MicroWires are… Tiny – 1cm of MicroWire with a diameter of ~50 micrometres is enough to sense data successfully. Biocompatible – they are made from non-harmful, non-toxic material. Contactless – they can provide measurements without any contact or wiring. Time, space and material efficient – 1g of alloy can make 1km of MicroWires in 10-15 minutes. Versatile – they can measure mechanical stress/strain, temperature, position, vibrations, and more. Sustainable – they increase effectiveness while reducing costs, downtimes, errors, and energy wastage. Revelatory – they can collect physical data from spaces that are not visible or audio-detectable. Streamlined – multiple MicroWires can feed into one interface. Non-destructive – they can monitor physical properties of goods without damaging their structure. The lightbulb moment? With over 30 years of experience in magnetism research, our CTO and founder, Professor Rastislav Varga, saw the vast potential of MicroWires for industrial applications. So, in 2015, he founded RVmagnetics. Today, he is backed by a team of 17 R&D professionals from different worlds – chemists, physicists, mechanical engineers, electronics engineers, and software developers. Together, we have over 80 years of combined experience developing MicroWires. An interesting fact about us: Our MicroWires have a glass coating, and the state, temperature, type, and material of this coating is important during the manufacturing of our sensors. Luckily, Tomaš – one of our scientists who has glass-working expertise – can tell if this glass coating is at the right temperature just from the smell in the room. Why did you apply for Sixth Sense? For us, identifying a correct use case with potential strategic partners like Hexagon is of utmost importance. The Sixth Sense programme is not only aimed at fully satisfying that process, but is also aligned with our focus on sustainability and innovation. Where do we hope to be in five years’ time? Looking at our current partners and customers, we are currently on the edge of getting a few of our exciting use cases into mass-manufactured state; becoming a supplier of MicroWires along with an R&D entity. In five years, we aim for this to be a reality. And in 2028/2029, we aim to be able to